It’s not everyday the folks over at Jack Daniel’s call you up and extend an invite to tour their cooperage, their distillery and rub shoulders with the Master Distiller. Luckily for you Busted Wallet, we’re on a short list of privileged media outlets to get an invite to what’s known as “Camp Jack.” If you’ve been following our Twitter and Instagram accounts you’ve got a pretty good idea of what we’ve been up to while we were in Nashville, Lynchburg and Alabama last week.

So, what is Camp Jack you ask? Good question… Camp Jack was initially developed to educate Jack Daniel’s employees on all there is to know about the history of the brand, how Tennessee Whiskey is made and everything else in between. What is usually a week long experience (for employees) was condensed in to a two day affair for our visit. Beginning with a trip to the Jack Daniel Cooperage in northern Alabama to see how American white oak barrels are manufactured.

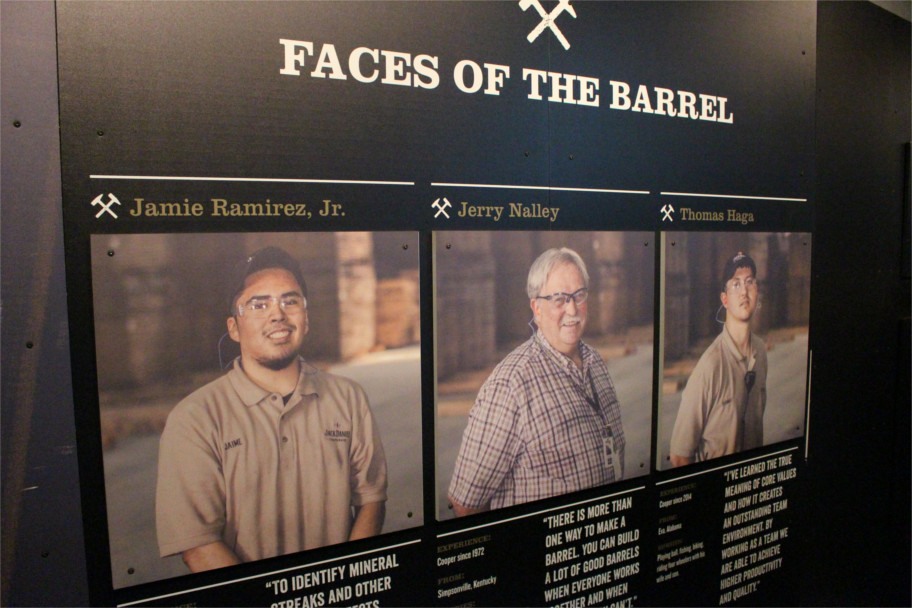

While they declined to show us the barrel ‘toasting’ process (their most heavily guarded secret) we did get to see, touch and hear every step of the barrel crafting process. If you didn’t already know, Jack Daniel’s is the only distillery in the world that makes their own whiskey barrels. They do it all! From rough wood to fully assembled, charred barrels. The Cooperage in Alabama pumps out 800 barrels daily and is a truly impressive manufacturing facility.

While they declined to show us the barrel ‘toasting’ process (their most heavily guarded secret) we did get to see, touch and hear every step of the barrel crafting process. If you didn’t already know, Jack Daniel’s is the only distillery in the world that makes their own whiskey barrels. They do it all! From rough wood to fully assembled, charred barrels. The Cooperage in Alabama pumps out 800 barrels daily and is a truly impressive manufacturing facility.

Once we wrapped up in Alabama, we were off to lunch. If you’re ever in Lynchburg, TN do yourself a favor and book a reservation at Miss Mary Bobo’s. It’s family style dining mixed with good ol’ southern cooking. We’re talking fried chicken, macaroni and cheese, sweet tea, fried okra, green beans, roasted potatoes and that’s just to name a few delicious menu items. My mouth is still watering.

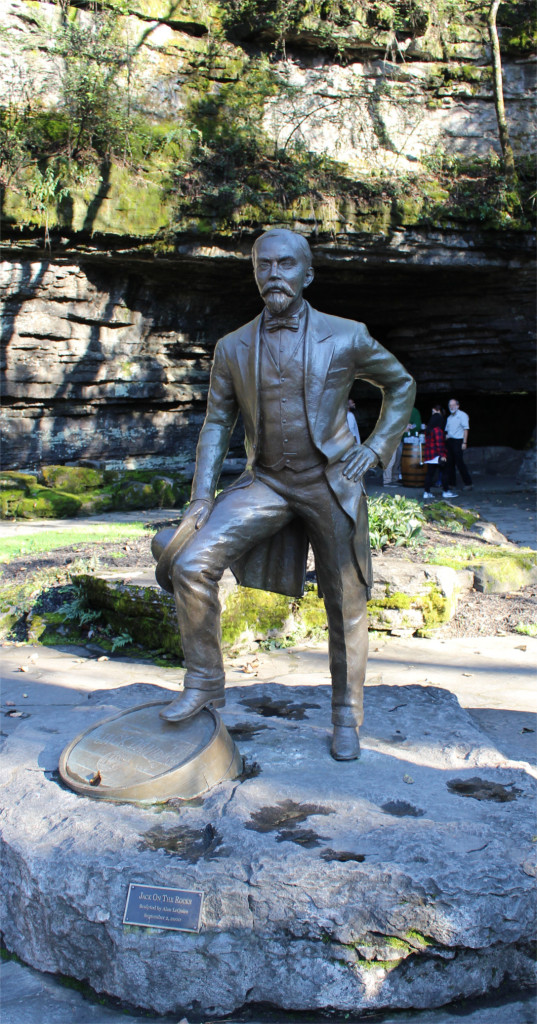

After lunch is where the real excitement happened for us. It was time for a tour of the Jack Daniel’s compound and America’s oldest registered distillery. When we arrived we were greeted with a couple fingers of Old No. 7 at the spring water cave where Jack Daniel’s started it all nearly 150 years ago. The spring water that flows from this cave is a constant 56 degrees year-round. The water isn’t pure enough to simply bottle and sell, but that didn’t stop us from taking a scoop and adding it to our whiskey, it just felt like the right thing to do.

After lunch is where the real excitement happened for us. It was time for a tour of the Jack Daniel’s compound and America’s oldest registered distillery. When we arrived we were greeted with a couple fingers of Old No. 7 at the spring water cave where Jack Daniel’s started it all nearly 150 years ago. The spring water that flows from this cave is a constant 56 degrees year-round. The water isn’t pure enough to simply bottle and sell, but that didn’t stop us from taking a scoop and adding it to our whiskey, it just felt like the right thing to do.

After a proper tour of the distillery with assistant master distiller Chris Fletcher it was time to meet up with the man in-charge… Jack Daniel’s 7th master distiller Jeff Arnett, who swiftly wrangled us up and trucked us over to barrel house 105, where we marched up to the 7th floor to tap a couple barrels of whiskey for tasting.

After a proper tour of the distillery with assistant master distiller Chris Fletcher it was time to meet up with the man in-charge… Jack Daniel’s 7th master distiller Jeff Arnett, who swiftly wrangled us up and trucked us over to barrel house 105, where we marched up to the 7th floor to tap a couple barrels of whiskey for tasting.

At this moment we were quite literally in whiskey heaven. It really doesn’t get much better than this. We were on the highest floor, in the tallest barrel house in Lynchburg. With the sun setting quickly Jeff took out his trusty hand-crank drill and proceeded to drill two holes in a barrel of JD single barrel. The first hole was a ‘breather’ while the second allowed the whiskey to flow. Earlier this summer we were given the opportunity to sample some single barrel barrel proof whiskey and were very impressed. On this day we were sipping the same product, but with one HUGE difference… we were actually drinking from the barrel. As I write this today I still find it a little surreal.

How did it taste? At nearly 130 proof it was incredibly flavorful and surprisingly mellow. Lots of oak flavoring, vanilla, and caramel. An experience I’ll never get tired of talking about.

After sipping a few ounces of single barrel barrel proof we walked 70 feet over to the left wing of the 7th floor where a totally new product is being aged and is nearly ready for bottling.

After sipping a few ounces of single barrel barrel proof we walked 70 feet over to the left wing of the 7th floor where a totally new product is being aged and is nearly ready for bottling.

Since the beginning Jack Daniel’s has always used the same recipe (grain bill) to make all of their variants. To distill Jack Daniel’s you need 80% corn, 8% rye and 12% malted barley. They’ve used this exact recipe for nearly 150 years. This same recipe is the base for Old No. 7, Gentleman Jack, Single Barrel and so on…

In 2016 they will be introducing a new Rye Whiskey. The recipe is totally new, and nearly the opposite of the original. For JD Rye, you’re looking at 70% rye, 12% malted barley and 18% corn. Just like he did earlier, Jeff pulled out the drill and tapped two holes in the rye barrel. Unlike the single barrel barrel proof we had just tasted the rye was quite spicy, noticeably more intense, but still maintained a very distinct Jack Daniel’s profile.

Once we sipped our last sip and took some pictures we were off to the tasting room for a formal, sit-down whiskey tasting with Jeff. He took us through every variant one sip at a time – from Old No. 7 to Single Barrel to Tennessee Honey, and everything in between.

Once we sipped our last sip and took some pictures we were off to the tasting room for a formal, sit-down whiskey tasting with Jeff. He took us through every variant one sip at a time – from Old No. 7 to Single Barrel to Tennessee Honey, and everything in between.

A very interesting part of the tasting was how it started. Jeff presented us with two white whiskies. One labeled “before mellowing” the other “after mellowing.”

If you don’t know what mellowing is let me quickly explain. Mellowing is a process where the whiskey is filtered through charcoal. The charcoal strips the spirit of impurities but adds nothing else. Before mellowing, Jack Daniel’s is actually considered a bourbon whiskey. Only after mellowing can it be bottled and sold as ‘Tennessee Whiskey.” Mellowing is an expensive process and only a handful of distillers are doing it these days.

When tasting both the before and after mellowing samples we were floored by the difference. The before is more harsh, with a very hot nose. The after mellowing sample was, well… more mellow to put it simply.

When the tasting was done we had sipped nine different whiskies. All very different, but all very Jack Daniel’s. It was time for dinner and then time for bed, because on the final day they were putting us to work. Seriously… they made us work.

On the final day we were greeted by Jeff and his crew. We started off with a history lesson and some incredible facts about Jack Daniel’s…

Did you know?

Did you know?

- Jack Daniel’s Tennessee Whiskey (Old No. 7) sells just over 12 million cases around the world each year

- For every 1,000,000 bottles sold, 3 complaints are logged

- Jack’s birth name was Jasper… would you drink Jasper Daniel’s Whiskey?

- Jack Daniel’s employees 100 whiskey tasters for quality control

- Whiskey is good forever if stored out of sunlight and in moderate temps

- Jack Daniel’s sends only 1% of it’s waste to the landfill each year

- Old No.7 bottles are made with 7% recycled glass

- It takes two men 1.5 hours to burn two cord of sugar maple used for mellowing

- Jack Daniel’s sells their spent grain to cow farmers

- They sell their ash from heating the stills and boilers to local farmers

- All corn used to make Jack Daniels is sourced in the USA

- Barrel houses are either 7 or 4 stories tall on JD property

- Rye must be sourced from Canada because it is scarce

- Jack Daniel’s strain of proprietary yeast is kept on back-up in a -81°F freezer

After we were properly schooled in all things Jack Daniel’s, we walked over to the Rickyard where we made charcoal from seasoned sugar maple. To light the fire that ignites the wood Jack Daniels uses high proof bourbon aka un-mellowed Jack Daniel’s to stoke the flames until the fire can sustain itself.

From here we took a stroll through the distillery stopping at the fermenters, mellowing vats, a quick stop in to quality control, which is more like a lab from CSI than I could have ever expected. And ended at the bottling line where everything was running like clockwork, until we arrived and slowed them down promptly by trying to apply labels ourselves. Sorry!

From here we took a stroll through the distillery stopping at the fermenters, mellowing vats, a quick stop in to quality control, which is more like a lab from CSI than I could have ever expected. And ended at the bottling line where everything was running like clockwork, until we arrived and slowed them down promptly by trying to apply labels ourselves. Sorry!

Before leaving Lynchburg we headed up to have some BBQ and Lyncburg lemonade from the comforts of JD’s on-site concert hall / barn that overlooks Lynchburg. The food was fantastic, but the view was truly amazing.

Before leaving Lynchburg we headed up to have some BBQ and Lyncburg lemonade from the comforts of JD’s on-site concert hall / barn that overlooks Lynchburg. The food was fantastic, but the view was truly amazing.

After lunch the crew from Jack Daniel’s said goodbye by giving us all nicknames. They say when you’re able to give someone a nickname they are a friend for life. With one last cheers Camp Jack was officially over. *single tear*

At the end of this day we walked away with a very good knowledge of whiskey distilling and a great understanding of the manpower it takes to run a global powerhouse like Jack Daniels. It’s truly overwhelming and hard to believe it is all done in the sleepy little town of Lynchburg. But I think the biggest thing we learned is that for 150 years Jack Daniel’s and its employees have been making whiskey the right way. They don’t take short cuts, they don’t skimp on

ingredients and they keep it honest. Never again will you hear us complain about a $19 bottle of Old No. 7 or a $45 bottle of Single Barrel. After seeing all the hard work that goes into each bottle how could we? Not to mention it tastes so damn good!

If you have a chance to visit Lynchburg, TN and the Jack Daniels Distillery don’t pass it up. While the regular tours won’t get you into the barrel house or job working on the bottling line – they are fun and informative. Heck nearly 300,000 visitors file through the doors each year. When you get there tell em’ Busted Wallet sent you!

Subscribing to your blog.